Geotextiles: Versatile Solutions for Civil Engineering

Geotextiles: A Foundation for Sustainable Construction

Geotextiles are essential components in modern civil engineering projects. These permeable textile materials are used in conjunction with soil, rock, or other materials to enhance project stability, drainage, and erosion control.

Key Functions of Geotextiles

Separation

Geotextiles prevent the mixing of different soil layers, ensuring proper drainage and stability.

Reinforcement

They reinforce the soil structure, improving its strength and resistance to deformation.

Filtration

Geotextiles allow water to pass through while retaining soil particles, preventing clogging and erosion.

Drainage

They enhance drainage by creating a permeable layer within the soil.

Moisture Barrier

Geotextiles can act as moisture barriers, preventing the movement of water into or out of specific areas.

Geotextiles in Stormwater Management

Geotextile fabrics play a crucial role in optimizing the functionality of soakwells. By preventing clogging, promoting proper drainage, and protecting the surrounding soil from erosion, geotextiles contribute to effective stormwater collection, treatment, and infiltration. This helps to reduce stormwater runoff and mitigate the impacts of flooding.

Our Range of Geotextile Products

Geotextile is any permeable textile material used with foundation, soil, rock, earth, etc. that is an integral part of a constructed project, structure or system. It may be made of synthetic or natural fibers.

It’s made from synthetic polymers – polypropylenes, polysters, polyethylenes and polyamids – which do not decay under biological and chemical process.

Made from synthetic fibers like polypropylene, polyesters, polyethylenes, and polyamids, our geotextiles are durable and resistant to decay.

Geotextile Fabric

Geotextile fabric is a permeable textile material used for soil

stabilization, filtration, drainage, and erosion control. The manufacturing process for geotextile fabric involves:

Fiber Selection

Synthetic fibers such as polyester or polypropylene are commonly used. The facility sources high-quality raw materials suitable for geotextile production.

Web Formation

The fibers are laid down in a web formation process using methods like needle punching, heat bonding, or weaving.

Consolidation

The web of fibers is consolidated through processes such as needle punching, thermal bonding, or chemical bonding to enhance strength and durability.

Finishing

Additional processes like calendaring, coating, or laminating may be applied for specific functionalities or to meet project

requirements.

Geocells

Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene (HDPE). They provide confinement for soil or aggregate materials, creating stable platforms for load support or erosion control. The manufacturing process involves:

Polymer Extrusion

HDPE is extruded into sheets with protruding cells or pockets.

Sheet Welding

The sheets are welded together to form a continuous,

interconnected honeycomb structure.

Panel Cutting

The continuous structure is cut into panels of desired sizes

Folding & Packaging

The panels are folded and packaged for transportation and use.

These 3D honeycomb-like structures, made from high-density polyethylene (HDPE), provide excellent confinement for soil or aggregate materials. They are ideal for load support and erosion control.

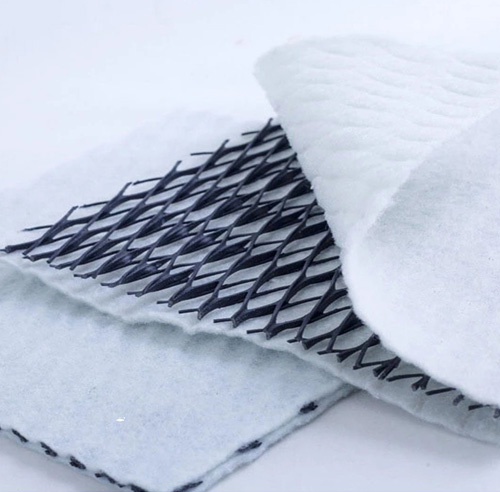

Geocomposite

Combinations

- Geotextile + Geogrid

- Geotextile + Geomembrane

- Geomembrane + Geogrid

Functions

- Separation

- Reinforcement

- Filtration

- Drainage

- Moisture Barrier

Combining geotextiles with geogrids or geomembranes, our geocomposites offer a versatile solution for various applications.

Benefits of Using Geotextiles

Enhanced Stability

Geotextiles improve the stability of foundations, slopes, and embankments.

Improved Drainage

They enhance drainage efficiency, preventing waterlogging and erosion.

Reduced Costs

Geotextiles can help reduce long-term maintenance costs by preventing premature failure of structures.

Environmental Benefits

They contribute to sustainable construction practices by reducing the environmental impact of projects.

Choose Our Geotextiles for Quality and Reliability

Our geotextile products are designed to meet the highest industry standards for quality and performance. We offer a wide range of options to suit your specific project needs. Contact us today to learn more about how our geotextiles can benefit your civil engineering projects.